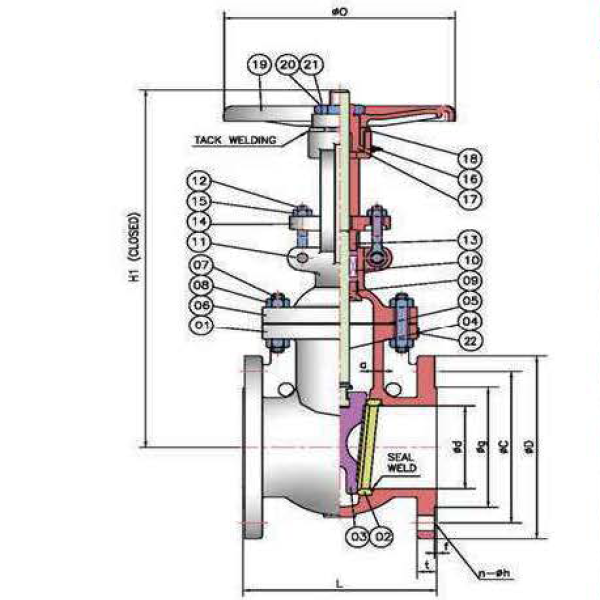

| Part and Material List | |||

|---|---|---|---|

| 01 | Body | Carbon Steel | ASTM A216 WCB |

| 02 | Body Seat Ring | Carbon Steel | ASTM A105 ST'L No. 6 Face |

| 03 | Wedge | Carbon Steel | ASTM A216 WCB 13Cr Face |

| 04 | Stem | Stainless Steel | ASTM A182 F6a |

| 05 | Gasket | Stainless Steel + Graphite | ASTM A182 316 + Graphite |

| 06 | Bonnet | Carbon Steel | ASTM A216 WCB |

| 07 | Bonnet Bolt | Carbon Steel | ASTM A193 B7 |

| 08 | Bonnet Nut | Carbon Steel | ASTM A194 2H |

| 09 | Back Seat Ring | Stainless Steel | ASTM A276 410 |

| 10 | Packing Ring | Graphite | Die Formed / Braided Graphite |

| 11 | Hinge Pin | Carbon Steel | - |

| 12 | Gland Bolt | Carbon Steel | ASTM A193 B7 |

| 13 | Packing Gland | Stainless Steel | ASTM A276 410 |

| 14 | Gland Flange | Carbon Steel | ASTM A216 WCB |

| 15 | Gland Nut | Carbon Steel | ASTM A194 2H |

| 16 | Grease Nipple | Stainless Steel | 2 1/2" Above |

| 17 | Yoke Sleeve | Ductlie Iron | ASTM A439 D2 |

| 18 | Yoke Cap | Carbon Steel | - |

| 19 | Handwheel | Ductlie Iron | - |

| 20 | Handwheel Nut | Carbon Steel | - |

| 21 | Set Screw | Steel | - |

| 22 | Nameplate | Stainless Steel | ASTM A182 F316 |

Other End connections are available on request.

Option available for materials to meet NACE MR0175 requirement

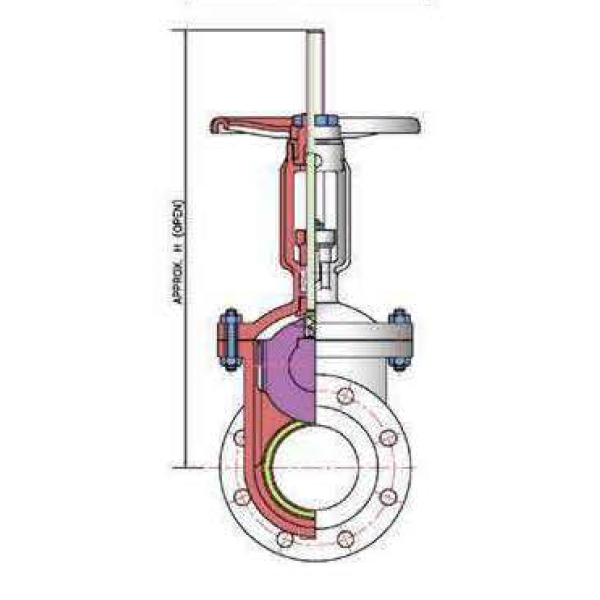

| Dimensional Data (mm)* | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2" | 292.0 | 50.8 | 165.0 | 127.0 | 92.1 | 25.4 | 7.0 | 8-19.1 | 250 | 458/400 | 11.2 | 46.0 |

| 2-1/2" | 330.2 | 63.5 | 190.5 | 149.4 | 104.6 | 28.5 | 7.0 | 8-22.5 | 250 | 475/403 | 11.9 | 55.0 |

| 3" | 356.0 | 76.2 | 210.0 | 168.3 | 127.0 | 31.8 | 7.0 | 8-22.4 | 250 | 546/460 | 12.7 | 72.0 |

| 4" | 432.0 | 101.6 | 275.0 | 215.9 | 157.2 | 38.1 | 7.0 | 8-25.4 | 350 | 680/570 | 16 | 128.0 |

| 6" | 559.0 | 152.4 | 355.0 | 292.1 | 215.9 | 47.7 | 7.0 | 12-28.6 | 450 | 850/675 | 19.1 | 266.0 |

| 8" | 660.0 | 199.9 | 420.0 | 349.2 | 269.9 | 55.6 | 7.0 | 12-32.0 | 310 | 1170/888 | 25.4 | 419.0 |

| 10" | 787.0 | 247.7 | 510.0 | 431.8 | 323.8 | 63.5 | 7.0 | 16-35.0 | 460 | 1327/995 | 28.7 | 754.0 |

| 12" | 838.0 | 298.5 | 560.0 | 489.0 | 381.0 | 66.7 | 7.0 | 20-35.0 | 540 | 1569/1169 | 31.8 | 981.0 |

| 14" | 889.0 | 326.9 | 605.0 | 527.0 | 412.8 | 69.9 | 7.0 | 20-38.0 | 610 | 1762/1298 | 35.1 | 1316.0 |

| 16" | 991.0 | 374.7 | 685.0 | 603.2 | 469.9 | 76.2 | 7.0 | 20-41.0 | 610 | 1905/1391 | 38.1 | 1672.0 |

| 18" | 1092.0 | 419.1 | 745.0 | 654.0 | 533.4 | 82.6 | 7.0 | 20-44.0 | 610 | 2051/1487 | 41.4 | 2070.0 |

| 20" | 1194.0 | 463.6 | 815.0 | 723.9 | 584.2 | 88.9 | 7.0 | 24-44.0 | 610 | 2320/1706 | 44.5 | 2405.0 |

| 24" | 1397.0 | 558.8 | 939.8 | 838.2 | 692.2 | 101.6 | 7.0 | 24-52.0 | 810 | 2725/1937 | 50.8 | 4550.0 |